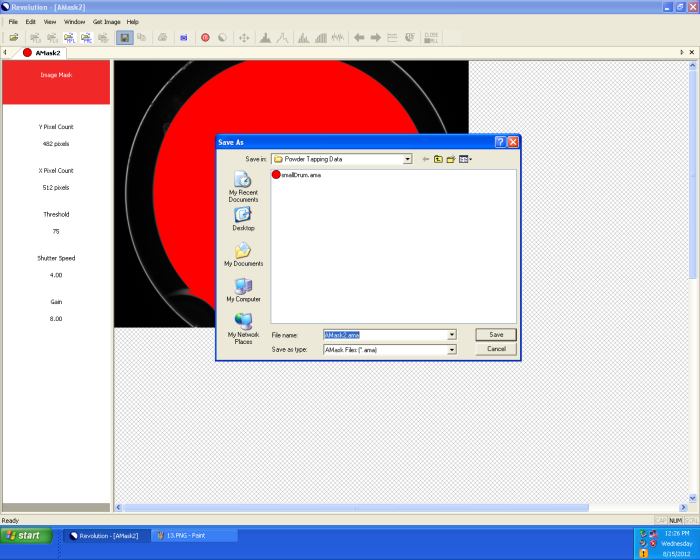

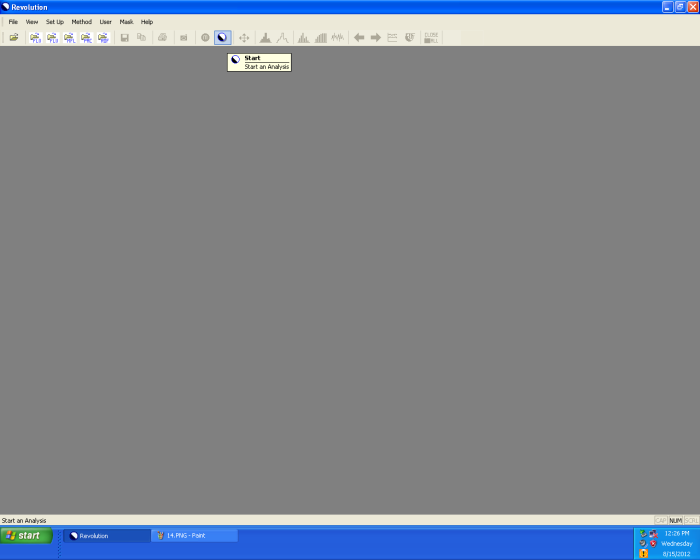

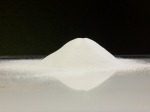

I’ve taken a look at a couple of papers both from the journal Pharmaceutical Research. Neither paper seemed concerned with the desegregation of the powders they were analyzing. The paper by Concessio et. al. did mention making mixtures with some of their powders (involving micronized albuterol sulfate) which they mentioned having mixed at 20rpm, but they didn’t mention whether this speed was determined to be the best or if it was arbitrarily chosen. To calculate the dynamic angle of repose they had a similar setup with a rotating drum rotating at .5 rpm, but once again it wasn’t mentioned why this speed was chosen. It seems that they captured video and then took measurements every 100ms to calculate the dynamic angle of repose of the powder. Another thing that caught my interest was that moisture contend did not seem to affect the static angle of repose as I would have assumed, perhaps surface morphology is a larger contributor to this factor. The second paper (by Lavoie et. al.) talked about the static angle of repose which was measured by letting powder drop from a funnel 5cm from the base until a stable cone was formed by the powder. Interestingly enough they also measured flowability and chose to measure this over wide set of speeds, unfortunately they didn’t gather any information regarding the dynmic angle of repose which would have been interesting to compare. Their static angle of repose method seemed to generate multiple angles of repose for a few powders as presented by their data. I wonder if this would also be true for the dynamic angle of repose except with a speed/rotation dependency. They defined some methods to determining cohesion and flowability indices, interestingly enough I didn’t see a significant correlation between these in the powders that they used (this is just a qualitative observation done by looking at some of their graphs/data presented). I’ve skimmed a few other papers but they weren’t as interesting as these two and none seemed to have any mention of rotation speed as a factor for the dynamic angle of repose in pharmaceutical powders. The best approach I can think of is taking multiple readings of the dynamic angle of repose at different speeds, and then performing a statistical test to determine whether any differences are significant.

Paper 1: DOI: 10.1023/A:1018865717374

Paper 2: DOI: 10.1023/A:1016125420577